Introduction

In manufacturing, Aluminum Extrusion stands out as a versatile and efficient process for creating complex shapes with excellent strength-to-weight ratios. When it comes to structural applications, the mechanical properties of aluminum extrusions play a crucial role. This article explores how alloy modifications can significantly enhance these properties, meeting the stringent demands of various industries.

Alloy Modifications in Aluminum Extrusion

Understanding Alloy Composition

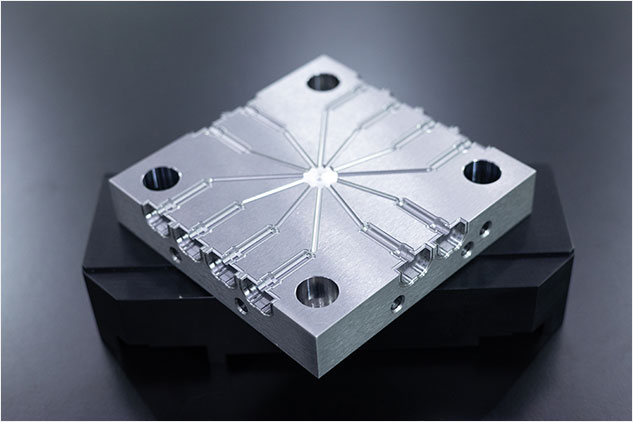

It’s essential to grasp the basics of aluminum extrusion die compositions to comprehend the impact of alloy modifications. Aluminum, inherently light and corrosion-resistant, gains remarkable strength through alloying with elements like copper, magnesium, and silicon. The proportions of these elements in the alloy are carefully adjusted to achieve specific performance characteristics.

Role of Alloy Modifications

Alloy modifications go beyond the basic composition, involving precise adjustments to enhance specific mechanical properties. For instance, increasing the content of certain elements can improve tensile strength, hardness, and overall durability. This fine-tuning is particularly valuable in structural applications where robustness is non-negotiable.

Examples of Common Alloy Modifications

Several alloy modifications are commonly employed to tailor aluminum extrusions to meet diverse needs. The addition of magnesium, for instance, results in alloys with enhanced strength, making them ideal for applications where structural integrity is paramount. These modifications ensure that custom aluminum extrusion profiles can be designed to meet specific project requirements.

Implications for Structural Applications

Overview of Structural Requirements

Structural applications span industries such as construction, aerospace, and automotive, each with unique demands. In construction, aluminum extrusions are often used for framing, curtain walls, and other load-bearing elements. Aerospace applications require materials that can withstand extreme conditions, emphasizing the need for enhanced mechanical properties.

Contribution of Enhanced Mechanical Properties

The alloy modifications discussed earlier directly address the requirements of structural applications. In construction, for example, where the balance between strength and weight is crucial, customized aluminum extrusions with improved mechanical properties offer a compelling solution. These extrusions provide the necessary power without adding unnecessary weight, contributing to the overall efficiency of the structure.

Case Studies Illustrating Successful Applications

Let’s delve into a few case studies to emphasize the practical implications. In a recent construction project, the implementation of alloy-modified Aluminum Extrusion profiles resulted in a structure that not only met but exceeded safety standards. The lightweight yet robust nature of the extrusions facilitated faster installation without compromising structural integrity.

In aerospace, alloy modifications played a pivotal role in developing aircraft components. These components exhibited increased strength, crucial for withstanding the demanding flight conditions while reducing overall weight.

This highlights how alloy modifications in aluminum extrusions directly translate into tangible benefits for structural applications.

Considerations for Users Seeking Aluminum Extrusion Services

Understanding Specific Project Requirements

Before delving into aluminum extrusion, users must first understand the specific requirements of their projects. Different applications necessitate varying degrees of strength, corrosion resistance, and thermal conductivity. By defining these parameters, users can work collaboratively with extrusion specialists to select or customize alloys that align with their project goals.

Collaboration with Extrusion Specialists

Aluminum extrusion die design and alloy selection require expertise. Collaborating with extrusion specialists early in the project development phase ensures users benefit from their knowledge and experience. Specialists can provide valuable insights into alloy choices extrusion techniques and even assist in optimizing designs for manufacturability.

Customization Options and Their Impact on Mechanical Properties

Customization is a hallmark of aluminum extrusion services. Users should explore the various customization options available, such as intricate profile designs or specific surface finishes. Notably, users need to understand how these customizations might impact the mechanical properties of the final product. The right balance ensures that the extruded components meet design specifications and performance expectations.

As users embark on the journey of utilizing custom aluminum extrusion services, these considerations serve as a roadmap for informed decision-making. The collaboration with specialists ensures that the chosen alloy modifications align with the project’s unique requirements.

Common User Questions and Answers

How do Alloy Modifications Affect Extrusion Costs?

One everyday concern users often have is how alloy modifications impact the overall cost of the aluminum extrusion process. While certain alloy modifications may incur additional charges due to using specific elements, it’s crucial to consider the long-term benefits. Enhanced mechanical properties can improve product performance, reducing maintenance and replacement costs over the product’s lifecycle.

Balancing Strength and Weight Considerations in Design

Achieving the right balance between strength and weight is paramount in structural design. Users may wonder how alloy modifications can help strike this balance. Alloy modifications allow for tailoring the material’s properties to meet the application’s specific requirements. This ensures that the extruded components provide the necessary strength without unnecessary weight, optimizing the overall performance of the structure.

Impact of Alloy Choice on Post-Extrusion Processes

Users often inquire about the post-extrusion processes and how alloy choice affects them. Certain alloys may respond differently to heat treatment, surface finishing, or other post-extrusion methods. Collaborating with extrusion specialists is crucial in understanding these nuances and ensuring that the chosen alloy aligns with the desired post-extrusion treatment for the best results.

Addressing these common questions helps users understand the implications of alloy modifications in Aluminum Extrusion for structural applications.

Industry Standards and Certifications

Overview of Relevant Standards for Structural Aluminum Extrusions

Ensuring that the aluminum extrusions meet industry standards is crucial for reliability and safety. Different sectors have specific standards governing the manufacturing and use of structural aluminum components. Understanding these standards is essential for users seeking extrusion services for structural applications. It ensures that the final product complies with industry norms and regulations.

Importance of Certifications for Ensuring Quality

Certifications add an extra layer of assurance regarding the quality of custom aluminum extrusions. Reputable extrusion specialists adhere to industry certifications, signifying their commitment to producing materials that meet or exceed recognized standards. Users should prioritize collaborating with extruders who hold relevant certifications, providing confidence in the reliability and consistency of the extruded components.

This section underscores the significance of adherence to industry standards and certifications in the realm of Aluminum Extrusion for structural applications.

Case Studies

Highlighting Successful Projects with Improved Mechanical Properties

Examining real-world examples is instrumental in understanding the practical impact of alloy modifications in Aluminum Extrusion. Several successful projects showcase how tailored alloy compositions enhanced mechanical properties and improved overall performance.

Case Study 1: Construction Project

In a recent construction project, the implementation of alloy-modified aluminum extrusions was pivotal. The structure’s load-bearing components, extruded with a customized alloy, demonstrated superior strength and durability. This met the stringent safety requirements and contributed to the project’s overall efficiency, thanks to the extrusions’ lightweight nature.

Case Study 2: Aerospace Application

Alloy modifications proved critical in the aerospace sector, where every ounce matters. Components extruded with a carefully crafted alloy exhibited increased strength without compromising weight. This resulted in aircraft components that met rigorous performance standards while contributing to fuel efficiency.

Lessons Learned and Best Practices

Analyzing these case studies allows users to glean valuable insights into the benefits and challenges associated with alloy modifications. It provides a foundation for establishing best practices in choosing, implementing, and optimizing alloy-modified aluminum extrusions for diverse applications.

Conclusion

In the realm of structural applications, the role of alloy modifications in Aluminum Extrusion is undeniably transformative. From enhancing mechanical properties to meeting specific project requirements, the precision offered by these modifications opens up a world of possibilities for designers and engineers alike.

As users navigate the landscape of custom aluminum extrusion services, understanding the intricate relationship between alloy modifications and structural performance becomes paramount. Collaboration with extrusion specialists, adherence to industry standards, and drawing insights from successful case studies collectively contribute to informed decision-making.

The journey from conceptualizing a project to witnessing its successful realization through extruded components involves carefully considering alloy choices, customization options, and post-extrusion processes. Each decision made along the way shapes the end product’s physical characteristics and overall efficiency, longevity, and adherence to safety standards.

In conclusion, as technology advances and demands for high-performance materials increase, the continuous refinement of alloy modifications in aluminum extrusion remains a driving force. Users embracing these advancements stand to benefit from structures and components that meet and exceed expectations, setting new standards for excellence in structural applications.

Feel free to let me know if you have any final thoughts, questions, or specific areas you would like to revisit. Otherwise, this concludes the article on the impact of alloy modifications in Aluminum Extrusion for structural applications.