Industry Experience

● Plastic and metal 1~3 days prototype production

● Quick quotation within 4 hours

● Machining accuracy 0.001mm

Manufacturing Services

Providing the production capacity you need to

help you with prototyping and production.

Rapid Prototyping

Out of creativity and imaginaton restraints,

quickly create personalized products.

Step Inside XTJ Company

Our company was established in 2005, specializing in precision parts, hardware molds, sheet metal and plastic models; business scope covers aviation, new energy Vehicles, medical equipment, household appliances, military, office equipment, 3D printing equipment, communications and other industries.

Our team is stable and technically capable. More than 300 employees, including more than 30 engineers, more than 40 quality inspectors; The average working experience of all employees is more than 5 years, among which the average working experience of the staff in the technical core position is more than 12 years. Our rich experience enables us to solve 99% of the production problems.

Services We Offer

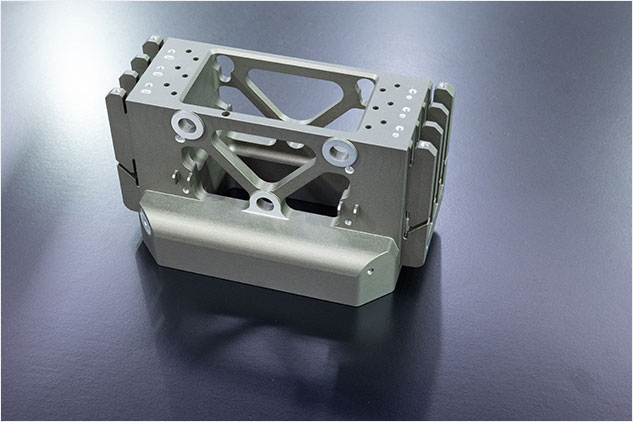

Five-axis CNC

High precision and difficult multi-surface machining is possible

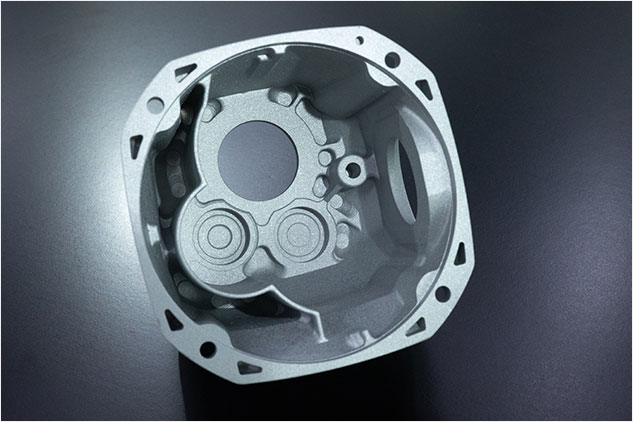

CNC Machining

Trustworthy China CNC machining manufacturer of plastic and metal custom CNC machined parts can be shipped as fast as 1-3 days.

CNC Lathe

We provide a full range of high-precision CNC turning services to customers in aerospace, automotive, medical equipment, robotics, 3D printers and many other industries.

Aluminum Extrusion

Our advanced machinery enables us to manufacture box section and open channel moulds in sizes ranging from 190 square mm to 280 x 60 mm.

Handcrafted models

Plastic exterior model

3D Printing

We are the expert in 3D printing in Asia, providing advanced 3D printing services including SLA 3D printing and SLS 3D printing.

Sheet Metal Stamping

Sheet metal stamping services can provide a quick and cost effective solution for your project.

Rapid Tooling

We have the equipment, skills and experience to help you create world class rapid molds for injection molding and pressure casting.

Quality Control

The company is certified to ISO 9001 (2015) quality management system, and also has SGS certification, ROHS environmental certification, EEC and TUV material-related certifications.

ISO 9001 sets the standard not only for quality management systems but also for overall management systems. It helps XTJ to achieve success through improvements in customer satisfaction, employee motivation and continuous improvement.

● IS0 9001: 2015

● IATF 16949:2016

● IS0 13485: 2016

Industries Service

The business scope covers aviation, medical equipment, household appliances, military, office equipment, 3D printing

equipment, communication and other industries.

Case Studies

Thousands of overseas cooperative customers

Get An Instant Quote For Your Next Projects.

We promise that any drawing files will be kept strictly confidential by us.

Blog

Thousands of overseas cooperative customers

Key Challenges in Automotive Prototyping: Material Selection and Structural Integrity

Introduction Automotive prototyping serves as a crucial stage in the development of vehicles, allowing engineers and designers to test and refine their designs before mass production. Among the numerous considerations in this process, material selection and ensuring structural integrity stand out as paramount. In this comprehensive discussion, we will delve into the intricate challenges inherent […]

How does material selection impact finishes and durability in Sheet Metal Stamping?

Introduction In the realm of precision manufacturing, Sheet Metal Stamping stands out as a versatile and widely used process. From producing intricate sheet metal stamping parts to crafting robust components, the success of this process often hinges on a crucial factor – material selection. Factors Influencing Material Selection When delving into the world of Sheet Metal Stamping, the […]

How is 3D printing transforming Automotive Prototyping and reshaping traditional manufacturing in the industry?

In the dynamic realm of automotive engineering, the process of Automotive Prototyping is undergoing a profound transformation, thanks to cutting-edge technologies such as 3D Printing and CNC machining. Introduction to 3D Printing At the forefront of this revolution stands 3D Printing, a disruptive technology reshaping how prototypes are conceived and developed. The efficiency gains and the ability to produce intricate designs […]