In the dynamic realm of automotive engineering, the process of Automotive Prototyping is undergoing a profound transformation, thanks to cutting-edge technologies such as 3D Printing and CNC machining.

Introduction to 3D Printing

At the forefront of this revolution stands 3D Printing, a disruptive technology reshaping how prototypes are conceived and developed. The efficiency gains and the ability to produce intricate designs have positioned 3D Printing as a cornerstone in the automotive design and manufacturing process.

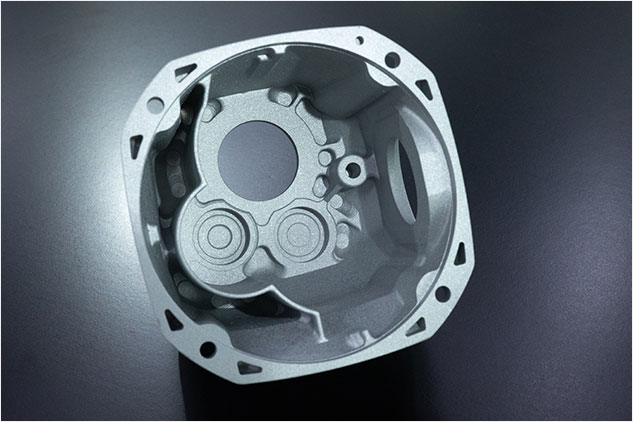

The Role of CNC Machining Parts

The integration of CNC machining parts further enhances the precision and reliability of prototypes. As we delve into the nuances of Automotive Prototyping, we’ll explore how these technologies collaborate to redefine the industry’s traditional norms.

The Evolution of Automotive Prototyping

Traditionally, automotive prototyping faced challenges such as extended production lead times and limitations in design complexity. The introduction of 3D Printing marked a turning point, allowing rapid prototyping and significantly reducing lead times. This shift in approach brings unparalleled agility to an industry where Innovation is synonymous with success.

Key Advantages of 3D Printing in Automotive Prototyping

Rapid Prototyping and Accelerated Design Iterations

3D Printing accelerates the development cycle by swiftly converting digital designs into physical prototypes. This agility is crucial in an industry where time-to-market is a critical factor.

Cost-Effectiveness and Reduced Production Lead Times

3D Printing minimizes material waste and reduces the need for expensive moulds or tooling, leading to substantial cost savings and more efficient production.

Enhanced Design Complexity and Customization Options

The intricate geometries achievable through 3D printing open new avenues for design innovation, allowing for customization with unparalleled precision.

Materials Innovation in 3D Printing

A diverse range of materials, including polymers, metals, and composites, are now compatible with 3D printing technologies. These materials offer diverse mechanical properties, addressing concerns related to strength, durability, and precision.

Case Studies: Successful Implementation of 3D Printing in Automotive Prototyping

Real-world applications illustrate the transformative impact of 3D Printing:

- Streamlining Design Iterations

- Complex Geometries for Improved Aerodynamics

- Customized Interior Components

These examples showcase the tangible outcomes, efficiency gains, and lessons learned through the integration of 3D Printing in Automotive Prototyping.

Addressing Common Concerns and Misconceptions

Addressing concerns related to material strength, precision, and production scalability empowers users to make informed decisions about integrating 3D Printing into their Automotive Prototyping endeavours.

Future Trends and Innovations

Emerging technologies such as multi-material Printing, generative design algorithms, and in-process monitoring are shaping the future of 3D Printing in Automotive Prototyping. The seamless integration of 3D Printing and CNC machining offers a comprehensive solution for prototyping.

Considerations for Users Seeking Automotive Prototyping Services

When choosing a prototyping service provider, factors such as technological expertise, material options, prototyping speed, and quality assurance processes are crucial. Leveraging 3D printing capabilities involves considerations such as customization, cost-efficiency, and a collaborative design process.

Conclusion

As technology advances, the synergy of 3D Printing and CNC machining in Automotive Prototyping reshapes the industry. Users can navigate this transformative landscape with confidence, armed with the knowledge to choose the right prototyping services and leverage 3D printing capabilities for innovative and efficient automotive projects.

For further exploration, dive into additional resources and references provided in the article. Stay informed, stay innovative!