On-demand Custom CNC Machining Services

Online CNC machining services for rapid prototypes and production parts in metals or plastics. Get instant quotes today, and order your custom CNC machined parts in a better price.

One-off CNC Prototypes

- 100K+ Mass Production Machining

- Tolerance as tight as ±0.01 mm

- Delivery in as little as 5 days

- Upload Your Files

Made to order from 1 to 10,000 pieces on demand

One-on-one support serviceResponse within 12 hours

In-house machine shop, 24/7 operations, Quick turnaround

Tight tolerance ±0.05mm Surface roughness Ra0.2μm

ISO 9001:2015 and AUTO41545 20221101 certified 100% part inspection

On Demand CNC Machining Services

Looking for a competitive advantage, rapid turnaround supplier for your CNC machining project? WayKen is an expert in CNC machining service in China for both prototypes and machined parts of end-use.

We offer a wide range of CNC machining services including milling and turning of various materials, as well as drilling, tapping, EDM (Electrical Discharge Machining), and wire EDM. Our ISO 9001 and AUTO41545 20221101 certified production process, combined with professional experiences and advanced CNC machines ensures your parts are made right the first time, every time.

Customers We Serve

Xintianjian provides excellent global services and has a large, rapidly growing customer base. Our customers are spread around the world and come from a wide variety of industries. It covers from independent inventors or designers to large scale Industrial, Commercial, Medical, Automotive, and even Aerospace companies. We will always do our best to meet your design and manufacturing needs, and help your ideas come to life.

On Demand CNC Machining Services

CNC maching

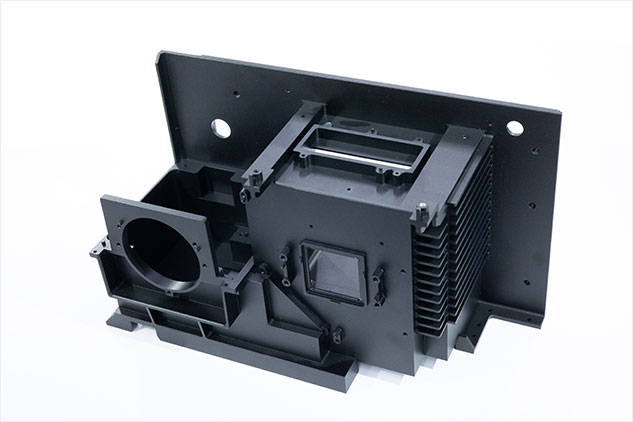

CNC machining is a subtractive fabrication method that uses a tool to move and rotate back and forth on the machine to remove material. CNC milling machines can be used cutting and machining operations on materials ranging from plastics to metals. It is suitable for various industries that require precision component processing, and is also the preferred solution for testing component functions in the early stage of manufacturing molds.

CNC Turning

CNC turning is a manufacturing process in which a bar of material is held in a chuck and rotated while a tool is injected to remove the material to create the desired shape. A turret, with tools attached is programmed to move the bar to the raw material and remove the material to create the programmed result. This is also called "subtractive machining" because it involves the removal of material.

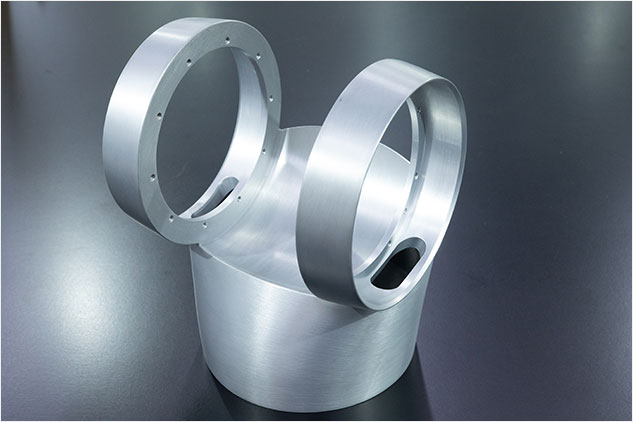

5-Axis CNC Machining

5 axis machining has unlimited possibilities, whether it is the size of the part or its shape, you can handle it effectively. On a 5-axis machining center, the tool moves through the X, Y and Z axes and rotates along the A and B axes to approach the workpiece from any direction.

The term "5-axis" refers to the number of directions the tool can move. In other words, you can handle five aspects of a part in one setup

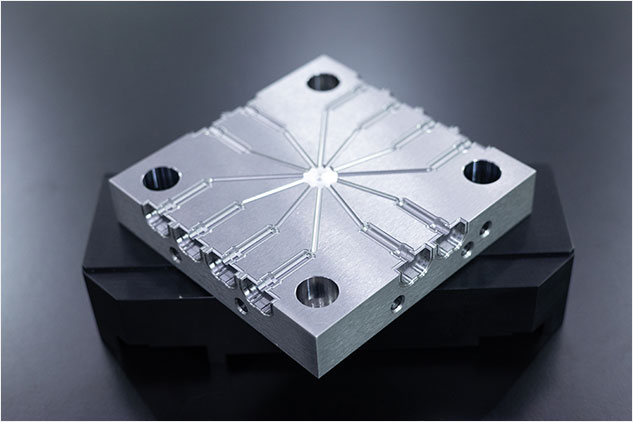

Precision CNC Machinin

Want to achieve precision tolerances of ±0.0005″ or higher? With mature professional knowledge, advanced CNC technology and inspection equipment, Xintianjian can provide customers with perfect accuracy and repeatability, even for complex problems. Components. We are committed to providing precision CNC machining perfection to meet or exceed all customer expectations.

CNC Machining Range Of Industries

● High precision machining of ±0.005mm.

● Labour savings and reduced machining problems.

● Reproducibility of components without reduction in production quality.

● Reduced material consumption through finely defined parameters.

● Flexibility in production lines.

● Versatility – CNC service makes milling of metals, steel and plastics possible

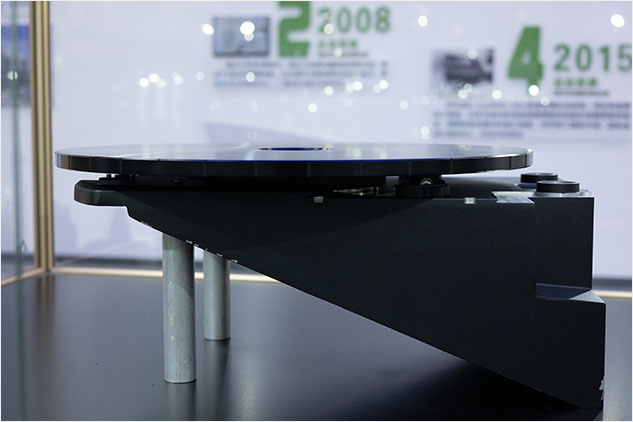

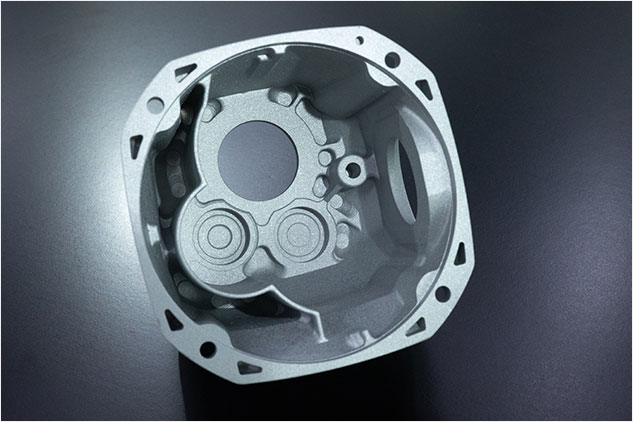

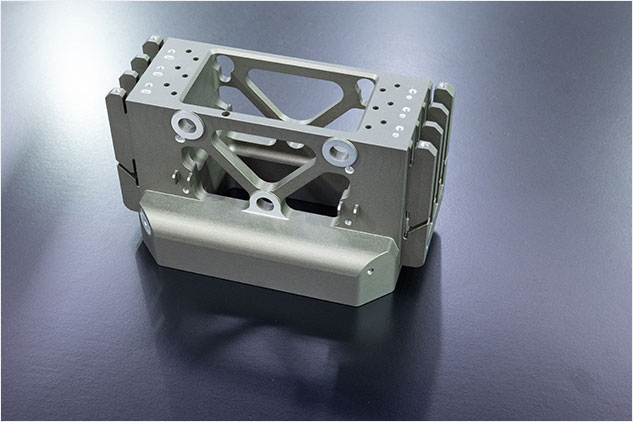

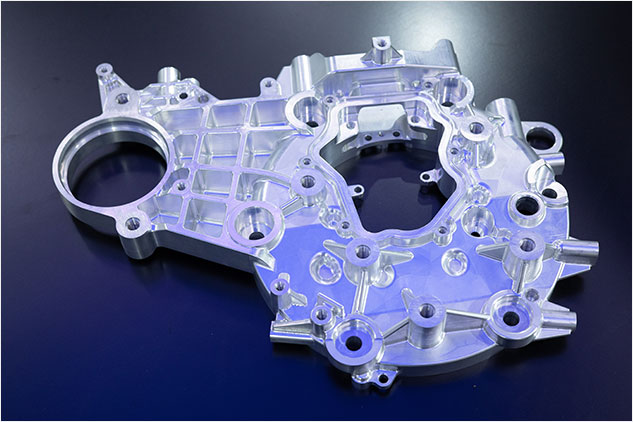

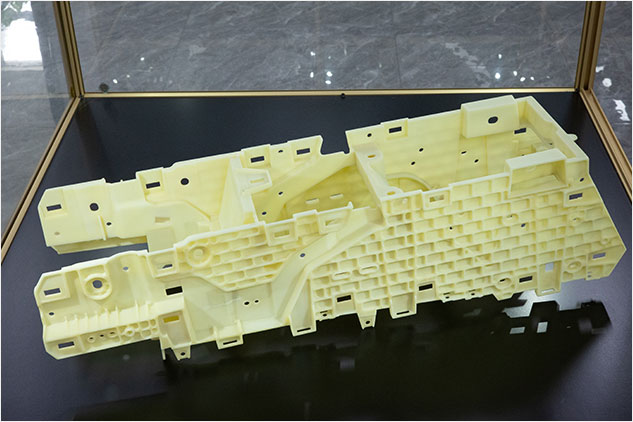

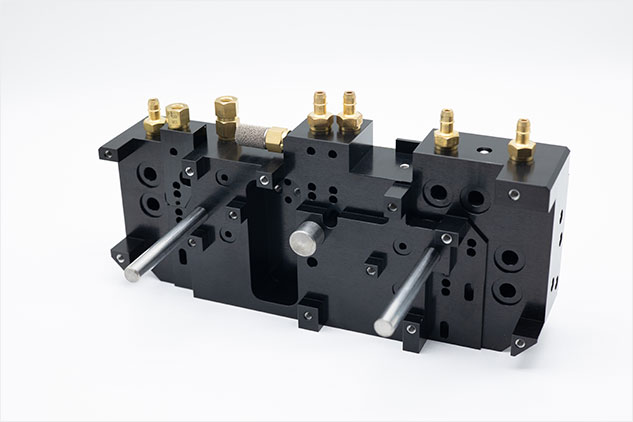

Production show

Advantages Of CNC Machining

01

High precision machining ±0.005

02

Fast delivery, as fast as 1-3 days. Ability to quickly verify the soundness of product design

03

Labor savings and reduction of machining problems

04

Reproducibility of elements without reducing production quality,New products quickly take over the market.

05

Flexibility of production lines

06

Versatility - Numerical control services enable the milling of metal, steel, and plastic

Why Choose us for

CNC Machining

Advanced equipment

High precision German imported 5-axis CNC

Excellent team

With over 15 years of industry experience engineers

Price advantage

With industry competitive price

Fast delivery

The fastest delivery time of 1-3 days

Advanced testing equipment

CMM, projector, height meter, micrometer and more than 20 testing instruments

Flexible solutions

Adjust our order and production plan according to customer’s needs at any time

Surface treatment

Sandblasting

● Supports a variety of surface bumping techniques.

● Increases surface area by surface bumping.

Reduces surface reflectivity.

● Effective use of substrate characteristics.

● Uniform concave and convex shapes can be produced.

Polishing

●Smooth a surface

●To prevent corrosion

●Remove oxide

●A smoother and brighter finish

Anodizing

●Prevent further oxidation

●Color by electrolysis

●The chemical properties are identical to those of alumina

Electropolishing

The surface of electropolishing products has no deteriorated layers and no additional stress, and the original stress layers can be removed or reduced.

The time of electropolishing is short, and multiple pieces at the same time is more efficient.

Difficult to use mechanical polishing hard materials, soft materials and thin wall, complex shape, small parts and products can be processed.

The surface roughness that can be achieved by electropolishing is related to the original surface roughness and can generally be improved by two levels.

Black Oxide

It is inevitable and feasible to choose black alumina ceramics as the research object. Because semiconductor integrated circuits often have obvious light sensitivity, the alumina used for the digital tube lining board is required to be black to ensure that the digital display is clear, and the special ceramic materials used to package the tube shell should have shading.

Powder Coating

Powder coating is a completely different form from the general coating, it is in the state of fine powder. Because no solvent is used, it is called powder coating. The main characteristics of powder coating are: harmless, high efficiency, saving resources and environmental characteristics.

Paint Spraying

Spray paint is a simple and widely used surface treatment process, is to put the paint into the container, the use of mechanical equipment after pressure, in the form of fog paint spray onto the product, forming a layer of paint film. Spray paint is widely used in ships, locomotives, Bridges, machinery and other fields. The main role of spray paint is to protect products or semi-finished products from rust and corrosion, but also to make products look more beautiful.

Our Partners

We provide exceptional global service with a large customer base. These customers are from all over the world and come from a wide range of industries, including automotive, aerospace, medical, 3d printers, communications and automation equipment. We have over 15 years of excellent service team to meet your requirements and help you make the parts you want!

Video

Get An Instant Quote For Your Next Projects.

We promise that any drawing files will be kept strictly confidential by us.